Quality

Integrity Machining is a business dedicated to all aspects of our Quality Management System (QMS) .

At Integrity, we realize that our equipment is just one part of what ensures quality; we must also ensure high quality at every other stage involved in getting a product to the customer. This involves inspections, process improvement, HR, finance, marketing, and so much more.

Temperature Control

From software to machine to finished product, there are many steps involved. For high-end machining, temperature and cleanliness is especially important for maintaining quality throughout every stage.

Our temperature-controlled facility allows us to eliminate environmental dangers and maintain tight/consistent precision.

Quality Control

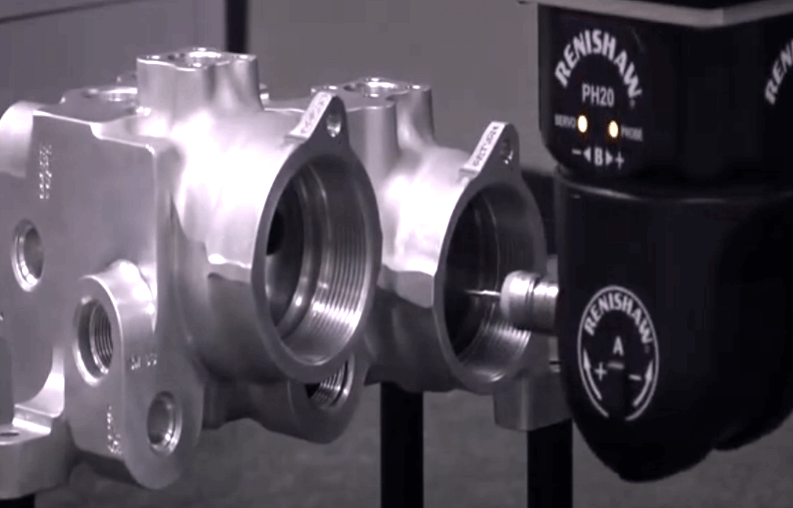

One of the most important aspects of quality control is our inspection processes. We consistently monitor our processes and inspect our first piece, in-process, and finished product to ensure accuracy, quality standards, and meeting customer requirements.

No project is too big or small to be excluded from our quality-control process.

Equipment

As a CNC machine shop with a high dedication to quality, our equipment is one of the most important ingredients in delivering your high-quality, perfectly-machined projects.

ISO 9100:2015 & AS 9100 Compliance

ISO 9100:2015 & AS 9100 Compliance